If you’re looking for an efficient way to manage your inventory, QR codes might be the solution you need. QR codes are two-dimensional barcodes that can be easily scanned by smartphones and other devices. They can hold a lot of information, such as product details, serial numbers, and locations, making them ideal for inventory management.

QR codes are easy to create and use, and they can save you a lot of time and effort. By using QR codes for inventory management, you can streamline your operations and reduce errors. You can track your inventory in real time, and you can quickly access the information you need to make informed decisions.

In this article, we’ll show you how to use QR codes for inventory management. We’ll explain how QR codes work, how to create them, and how to use them to track your inventory. We’ll also provide some tips and best practices to help you get the most out of QR codes for inventory management.

- QR Codes: The Perfect Solution for Inventory Management

- What are QR Codes?

- The Benefits of QR Codes in Inventory Management

- How to Implement QR Codes in Inventory Management

- Case Studies

- Why QR Codes are Useful for Inventory Management

- How to Scan QR Codes for Inventory Management

- How to Store QR Code Data for Inventory Management

- Best Practices for Using QR Codes for Inventory Management

- How to Create a QR Code with QRMAGICK

- Conclusion

QR Codes: The Perfect Solution for Inventory Management

QR codes are becoming increasingly popular in inventory management due to their ability to hold large amounts of data and their fast scanning capabilities. With the rise of e-commerce and online shopping, businesses need to efficiently manage their inventory to keep up with demand. QR codes offer a solution to this problem by streamlining the inventory management process.

According to a study conducted by Auburn University, using QR codes for inventory tracking can reduce time spent managing inventory by up to 50%.

QR codes were originally designed for the automotive industry in Japan in the 1990s, but have since been adopted by various industries for different purposes. In inventory management, QR codes can be used to track products, assets, equipment, processes, and services. By scanning a QR code, employees can quickly access information about the product or asset, such as its location, quantity, and expiration date.

QR codes are also cost-effective and easy to implement. They can be created and printed in-house, eliminating the need for expensive equipment or third-party services. Additionally, QR codes can be scanned using smartphones, which most employees already have, making it a convenient and accessible solution for businesses of all sizes.

What are QR Codes?

QR codes, or Quick Response codes, are two-dimensional square barcodes that can store a large amount of data in a small space. They were first developed in the 1990s by Japanese developers to provide more inventory-tracking data than a traditional barcode.

QR codes are made up of black and white squares arranged in a specific pattern. They can be scanned using a smartphone camera or a QR code scanner app, which can quickly and easily retrieve the data stored within the code.

QR codes are more advanced than traditional barcodes because they can hold more data and information, making them ideal for inventory management. They can also be customized with colors, logos, and other branding elements to make them more visually appealing and recognizable.

QR codes are already being used extensively in inventory management, as they can help businesses of all sizes keep track of their inventory more efficiently. By scanning a QR code, employees can quickly access information about a product, such as its location, quantity, and other important details.

The Benefits of QR Codes in Inventory Management

Improved Efficiency

QR codes can significantly improve efficiency in inventory management by streamlining the processes involved. With QR codes, inventory managers can easily track and manage inventory, making it easier to identify and address issues. QR codes can also help to reduce the amount of time spent on data entry, allowing teams to focus on other administrative tasks.

QR codes can be generated in bulk, making it easy to assign them to products and track them throughout the supply chain. This can help to reduce the amount of time spent on manual data entry and ensure that inventory records are accurate and up-to-date.

Real-Time Tracking

One of the biggest benefits of using QR codes for inventory management is the ability to track inventory in real time. This allows businesses to identify issues quickly and take corrective action before they become bigger problems.

According to a report by Zebra Technologies, companies that use real-time inventory tracking have seen a 25% reduction in excess inventory.

QR codes can be scanned using a smartphone or tablet, making it easy to track inventory as it moves through the supply chain. This can help to improve inventory accuracy and reduce the risk of stockouts or overstocking.

Reduced Errors

QR codes can help to reduce errors in inventory management by automating the tracking process. This can help to eliminate errors caused by manual data entry and reduce the risk of stockouts or overstocking.

A study by the National Center for Biotechnology Information found that using QR codes can reduce data entry errors by up to 99%.

QR codes can also help to reduce the risk of errors caused by human error. By automating the tracking process, businesses can ensure that inventory records are accurate and up-to-date, reducing the risk of errors that can lead to lost sales or unhappy customers.

How to Implement QR Codes in Inventory Management

Choosing the Right QR Code Generator

When implementing QR codes in inventory management, it’s essential to choose the right QR code generator. There are various types of QR code generators available, and it’s essential to select one that meets your specific needs. Dynamic QR code generators are recommended for inventory management as they allow for real-time updates and tracking. Additionally, consider the following factors when choosing a QR code generator:

- Cost

- Customization options

- Scanning compatibility with your devices

Labeling and Placement

Proper labeling and placement of QR codes are crucial for their effectiveness in inventory management. Ensure that each item has a unique QR code label that is easily scannable. Place the labels in visible locations that are easily accessible to employees. Consider using durable materials to ensure the labels don’t fade or fall off over time.

Training Employees

Training employees on how to use QR codes in inventory management is essential for the system’s success. Provide clear instructions on how to scan and update the QR codes in real-time. Additionally, ensure that employees understand the importance of accurate data entry and the consequences of incorrect entries. Regular training sessions can help reinforce the importance of using QR codes in inventory management effectively. Implementing QR codes in inventory management can streamline processes and improve efficiency. By choosing the right QR code generator, properly labeling and placing the codes, and training employees, businesses can maximize the benefits of this technology.

Case Studies

QR codes have been widely used in inventory management due to their fast scanning capabilities and ease of use. Let’s take a look at some case studies where QR codes have been implemented successfully:

Toyota

In the early 1990s, Toyota discovered that the barcode system they were using to track parts was running out of capacity. The number of components the company used was about to exceed the maximum number of items they could encode in a standard barcode. To solve this problem, Toyota turned to QR codes. By using QR codes, Toyota was able to encode much more information than it could with barcodes. This allowed them to track parts more efficiently and reduce inventory errors.

ASAP Systems

ASAP Systems is a provider of inventory management and asset tracking software. They have implemented QR codes into their system to make it easier for their customers to track their inventory and assets. With the QR code inventory management feature, third-party individuals or organizations without access to the system can scan QR codes and access published information. This makes it easy for customers to share information about their inventory and assets with others.

University of St. Andrews

The University of St. Andrews in Scotland implemented QR codes in its library to make it easier for students to find books. Each book in the library was given a unique QR code, which students could scan with their smartphones to get information about the book and its location in the library. This made it much easier for students to find the books they needed and reduced the amount of time they spent searching for books.

These case studies demonstrate the effectiveness of QR codes in inventory management. By using QR codes, companies and organizations can track their inventory and assets more efficiently and reduce errors. QR codes are easy to use and can be scanned quickly, making them a valuable tool for inventory management.

Why QR Codes are Useful for Inventory Management

Inventory management can be a challenging task, especially for businesses that deal with a large number of products. QR codes can be a game-changer for such businesses. Here are some reasons why QR codes are useful for inventory management:

- Fast Scanning: QR codes can be scanned quickly, making the inventory management process faster and more efficient. This is because QR codes can be scanned using a smartphone or a barcode scanner, and the information can be retrieved within seconds.

- Flexibility: QR codes can store different types of data, such as text, URLs, images, and videos. This makes them more flexible than traditional barcodes that only contain numerical data. Businesses can use QR codes to store product information, such as product name, description, price, and even location.

- Accuracy: QR codes are less prone to errors than traditional barcodes. This is because QR codes can store more data, which reduces the chances of a scanning error. QR codes can also be printed in high resolution, ensuring that they are easily scannable.

- Streamlined Inventory Management: QR codes can help businesses streamline their inventory management processes. By using QR codes, businesses can track their inventory throughout the supply chain, from the warehouse to the store shelves. This can help businesses reduce errors, minimize stockouts, and optimize their inventory levels.

In summary, QR codes can be a valuable tool for businesses that want to improve their inventory management processes. By using QR codes, businesses can streamline their inventory management, reduce errors, and improve efficiency.

How to Scan QR Codes for Inventory Management

Scanning QR codes for inventory management is a simple process that can be done with a smartphone or a QR code scanner. Here are the steps to follow:

- Open the QR code scanner app on your smartphone or scan the QR code using your scanner.

- Point your camera at the QR code and wait for the scanner to recognize it.

- Once the QR code has been recognized, the scanner will automatically decode it and display the information stored in the code.

- Review the information displayed on your device to confirm that it matches the item you are scanning.

- If the information is correct, you can then update the inventory records in your system accordingly.

It’s important to ensure that your QR code scanner is set up properly and is compatible with the QR codes you are using. Some scanners may have difficulty reading certain types of QR codes, so it’s important to test your scanner with different codes and adjust the settings as necessary.

It’s also important to ensure that the QR codes are placed in a location that is easy to scan and that the information stored in the code is accurate and up-to-date. This will help to ensure that your inventory records are accurate and that you can easily track your inventory levels.

How to Store QR Code Data for Inventory Management

Once you have generated QR codes for your inventory, you need to store the data in a way that is easily accessible and organized. Here are some tips on how to store QR code data for inventory management:

- Cloud-based storage: Consider using cloud-based storage solutions like Google Drive or Dropbox to store your QR code data. This way, you can access the data from anywhere and collaborate with team members easily.

- Spreadsheet: Use a spreadsheet to keep track of your QR code data. This will help you organize the data and make it easy to sort and filter. You can use tools like Microsoft Excel or Google Sheets for this purpose.

- Inventory management software: If you have a large inventory, consider using inventory management software that is designed to work with QR codes. This software will help you track inventory levels, generate reports, and automate tasks.

It’s important to keep your QR code data up-to-date and accurate. Make sure to update the data whenever there are changes to your inventory, such as new items being added or old items being removed.

In addition to storing the data, it’s also important to keep the physical QR codes organized. Consider using a labeling system to keep track of which QR code corresponds to which item in your inventory. This will make it easier to scan the codes and update the data as needed.

By following these tips, you can ensure that your QR code data is stored in a way that is organized, accessible, and up-to-date. This will help you streamline your inventory management processes and make informed business decisions.

Best Practices for Using QR Codes for Inventory Management

QR codes are an efficient and cost-effective way to manage inventory. However, using them effectively requires some best practices. Here are some tips to help you get the most out of your QR code inventory management system:

- Use high-quality QR codes: Ensure that your QR codes are high-quality and can be easily scanned. Poor quality codes can lead to scanning errors, making inventory management more difficult.

- Keep QR codes clean and unobstructed: QR codes should be free from any obstructions, such as dirt or other markings, that could interfere with scanning. Keep them clean and unobstructed to ensure accurate scanning.

- Place QR codes in strategic locations: Place QR codes in strategic locations where they can be easily scanned by employees. This will help ensure that inventory is accurately tracked and managed.

- Use unique QR codes: Use unique QR codes for each item in your inventory. This will help you track each item individually and ensure that you have an accurate count of your inventory.

- Regularly update QR codes: Regularly update QR codes to ensure that they are accurate and up-to-date. This will help prevent errors and ensure that your inventory is managed effectively.

By following these best practices, you can ensure that your QR code inventory management system is efficient, accurate, and effective. With the right approach, QR codes can be a powerful tool for managing your inventory and streamlining your operations.

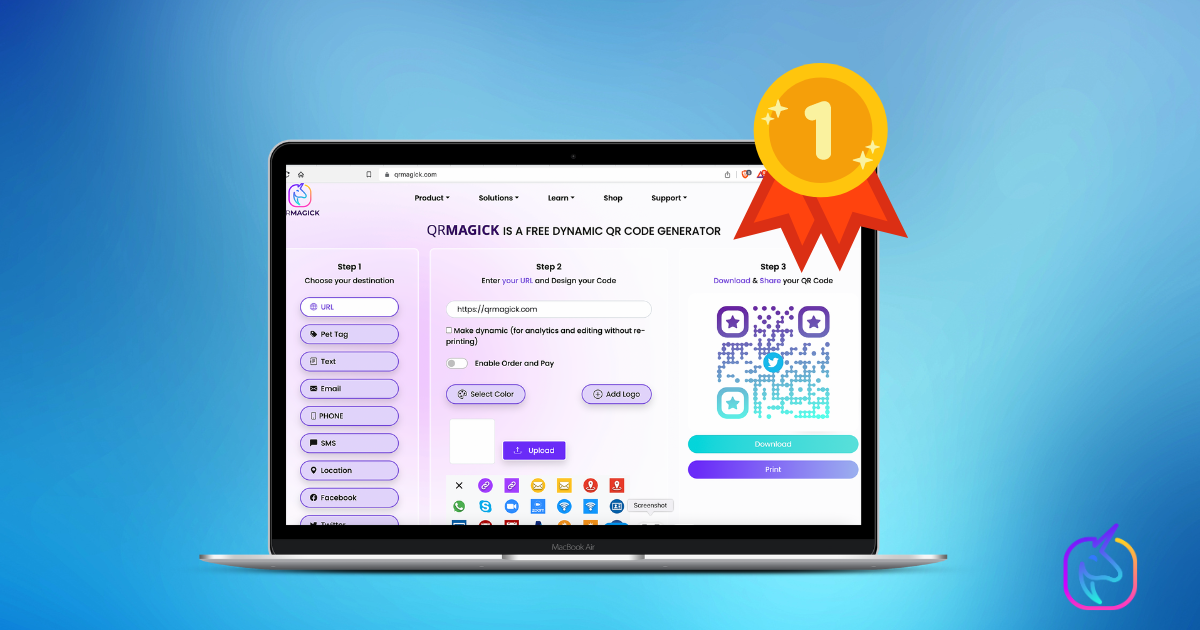

How to Create a QR Code with QRMAGICK

Creating QR codes for your inventory management system is a straightforward process. Follow these steps:

- Step 1: Go to www.qrmagick.com

- Step 2: Decide what information you want to encode in the QR code. This could include the product name, SKU number, location, and other relevant details.

- Step 3: Enter the information into the QR code generator. Make sure to choose the appropriate QR code type, such as static or dynamic, depending on your needs.

- Step 4: Customize the QR code’s appearance, if desired. You can choose from various colors, shapes, and sizes to make it stand out.

- Step 5: Download the QR code and print it out. Make sure to test it to ensure that it works properly before using it in your inventory management system.

It’s important to note that QR codes are editable, which means that you can update the information encoded in them at any time. This makes them a flexible and convenient tool for inventory management.

Conclusion

QR codes have revolutionized inventory management for businesses of all sizes. They have made the process of tracking inventory faster, more accurate, and less prone to human error. QR codes are easy to use and can be scanned using a smartphone or tablet, making them a cost-effective solution for businesses looking to streamline their inventory management processes.

By using QR codes, businesses can track their inventory in real time, making it easier to manage stock levels and prevent stockouts. QR codes also provide businesses with valuable data insights, such as sales trends and stock turnover rates, which can be used to optimize inventory management processes and improve profitability.

However, it’s important to note that QR codes are not a one-size-fits-all solution. They work best when integrated with other inventory management tools, such as barcode scanners and inventory management software. Additionally, businesses should ensure that their QR codes are properly formatted and placed in strategic locations to ensure optimal scanning.

Create your own QR Codes for Inventory Management for free with QRMAGICK today!

No responses yet